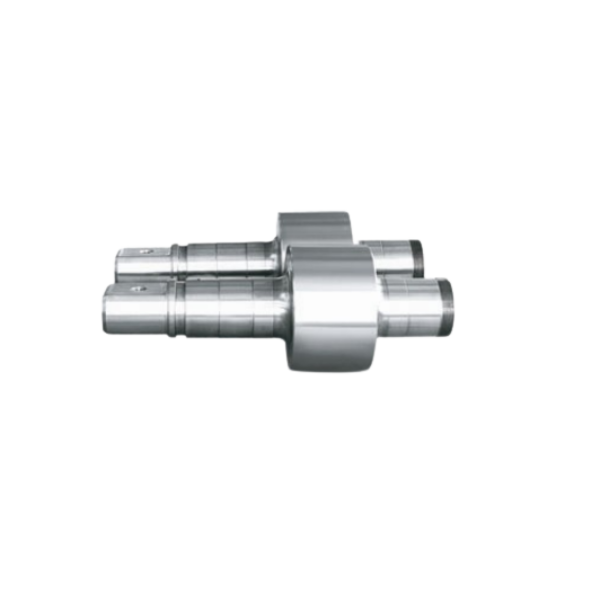

Alloy Nodular Iron Rolls

Alloy Nodular Cast Iron Rolls are widely used rolls in the steel and metallurgical industries, known for their excellent combination of toughness, wear resistance, and strength. By alloying nodular cast iron with elements such as nickel, chromium, and molybdenum, these rolls achieve a balanced microstructure that ensures reliable performance under demanding rolling conditions.

Properties of Alloy Nodular Iron Rolls

| Material Name | Code | C | Si | Mn | P | S | Cr | Ni | Mo | V | Mg | Barrel Hardness (HSD) | Neck Hardness (HSD) | Recommended Application |

| Chromium-Molybdenum Alloy Nodular Semi-Chilled Cast Iron Roll | SGB | 2.90–3.60 | 0.80–2.50 | 0.40–1.20 | ≤0.25 | ≤0.03 | 0.20–0.60 | — | 0.20–0.60 | — | ≥0.04 | 40–55 | 32–50 | Section steel roughing rolls |

| Chromium-Molybdenum Alloy Nodular Indefinite Chilled Cast Iron Roll | SG | 2.90–3.60 | 0.80–2.50 | 0.40–1.20 | ≤0.25 | ≤0.03 | 0.20–0.60 | — | 0.20–0.60 | — | ≥0.04 | 50–70 | 35–55 | Wire rod, section steel roughing rolls, strip steel work rolls |

| Nickel-Chromium-Molybdenum Alloy Nodular Indefinite Chilled Cast Iron Roll I | SG I | 2.90–3.60 | 0.80–2.50 | 0.40–1.20 | ≤0.25 | ≤0.03 | 0.20–0.60 | 0.50–1.00 | 0.20–0.80 | — | ≥0.04 | 50–65 | 35–55 | |

| Nickel-Chromium-Molybdenum Alloy Nodular Indefinite Chilled Cast Iron Roll II | SG II | 2.90–3.60 | 0.80–2.50 | 0.40–1.20 | ≤0.20 | ≤0.03 | 0.30–1.20 | 1.01–1.50 | 0.20–0.80 | — | ≥0.04 | 55–70 | 35–55 |

Key Characteristics

- High Strength & Toughness – The nodular graphite structure enhances impact resistance while preventing brittleness.

- Wear Resistance – Alloying elements improve hardness and extend service life, even under high rolling pressure.

- Thermal Stability – Excellent resistance to thermal fatigue and heat checking, ensuring consistent performance in hot rolling applications.

- Versatility – Suitable for both roughing and finishing stands in rolling mills.

Typical Applications

Alloy Nodular Cast Iron Rolls are commonly used in:

- Hot strip mills

- Bar and wire rod mills

- Section mills

- Medium and heavy plate mills

Comparison of Nodular Cast Iron Rolls

| Feature | Bainitic Nodular Cast Iron Rolls | Pearlitic Nodular Cast Iron Rolls | Alloy Nodular Cast Iron Rolls |

|---|---|---|---|

| Matrix Structure | Bainitic matrix with nodular graphite | Pearlitic matrix with nodular graphite | Alloyed pearlitic/bainitic matrix with nodular graphite |

| Hardness Range | 350–500 HB | 300–380 HB | 350–450 HB (depending on alloy & heat treatment) |

| Wear Resistance | ★★★★☆ High | ★★☆☆☆ Medium | ★★★★☆ High (better than standard pearlitic) |

| Toughness / Crack Resistance | ★★★★☆ Excellent | ★★★☆☆ Good | ★★★★☆ Excellent |

| Thermal Stability | ★★★★☆ Excellent | ★★☆☆☆ Moderate | ★★★★☆ Very Good |

| Service Life | Long, ideal for heavy-duty mills | Moderate, shorter under heavy load | Long, suitable for both heavy & medium-duty rolling |

| Applications | Roughing stands, section & bar mills, blooming mills | Finishing stands, medium-duty section mills | Versatile – hot strip roughing & finishing, bar & section mills |

| Cost Efficiency | Higher cost, lowest cost per ton in harsh conditions | Lower cost, economical for medium-duty | Balanced – slightly higher cost than pearlitic but more durable |

Why Choose Alloy Nodular Cast Iron Rolls?

Compared with pearlitic nodular rolls or bainitic nodular rolls, alloy nodular rolls offer superior strength and wear resistance, making them ideal for mills that require both durability and cost efficiency. They strike the right balance between hardness and toughness, reducing roll consumption and downtime. Contact Us for a best solution for your rolling mill!