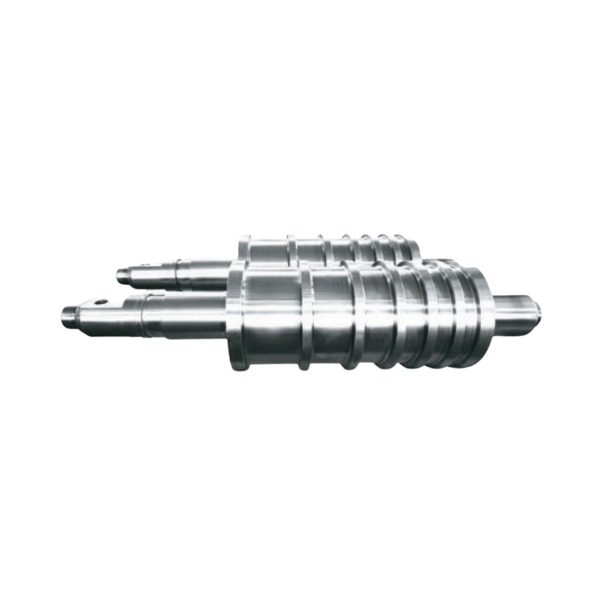

Alloy Cast Steel Rolls

What are Alloy Cast Steel Rolls?

Alloy cast steel rolls are essential in modern rolling mills, offering high strength, toughness, and excellent wear resistance. Produced with alloyed steel and elements such as chromium, nickel, and molybdenum, these rolls deliver superior thermal stability and long service life.

Key Benefits

Properties of Alloy Cast Steel Rolls

| Material Type | Grade | Chemical Composition (wt.%) | Surface Hardness / HSD | Recommended Applications |

|---|---|---|---|---|

| Alloy Steel | AS40 | C: 0.35–0.45, Si: 0.20–0.60, Mn: 0.60–1.20, Cr: 2.00–3.50, Ni: 0.20–0.80, Mo: 0.30–0.70, V: 0.05–0.20 | Barrel: 45–55, Neck: ≤45 | Hot-rolled strip roughing rolls and supporting rolls Cold and hot-rolled strip supporting rolls and leveling machines Supporting roll section steel roughing rolls |

| AS45 | C: 0.40–0.50, Si: 0.20–0.60, Mn: 1.00–1.20, Cr: 3.00–5.50, Ni: 1.00–2.00, Mo: 0.40–1.00, V: 0.05–0.30, Nb: 0.00–0.30 | Barrel: 55–65, Neck: ≤45 | ||

| AS50 | C: 0.45–0.55, Si: 0.20–0.60, Mn: 1.00–1.20, Cr: 1.00–3.00, Ni: 0.30–1.00, Mo: 0.30–0.60, V: 0.15–0.50 | Barrel: 55–60, Neck: ≤45 | ||

| AS55 | C: 0.50–0.60, Si: 0.20–0.60, Mn: 0.90–1.20, Cr: 0.80–1.20, Mo: 0.20–0.45 | Barrel: 60–70, Neck: ≤45 | Hot-rolled strip roughing rolls and section steel roughing rolls; billet-opening rolls for roll guides | |

| AS60 | C: 0.55–0.65, Si: 0.20–0.60, Mn: 1.00–1.20, Cr: 0.80–1.20, Ni: 0.20–1.50, Mo: 0.20–0.60 | Barrel: 35–45, Neck: ≤45 | ||

| AS65 | C: 0.60–0.70, Si: 0.20–0.60, Mn: 0.70–1.20, Cr: 0.80–1.20, Mo: 0.20–0.45, Nb: 0.06–0.10 | Barrel: 35–45, Neck: ≤45 | ||

| AS65 I | C: 0.60–0.70, Si: 0.20–0.60, Mn: 0.50–0.80, Cr: 0.80–1.20, Ni: 0.20–0.50, Mo: 0.20–0.45 | Barrel: 35–45, Neck: ≤45 | ||

| AS70 | C: 0.65–0.75, Si: 0.20–0.60, Mn: 0.90–1.20, Cr: 1.20–1.80 | Barrel: 32–42, Neck: ≤42 | Square billet roughing rolls Hot-rolled strip roughing rolls Vertical rolls Section steel and roll guide billet-opening rolls | |

| AS70 I | C: 0.65–0.75, Si: 0.20–0.60, Mn: 1.40–1.80 | Barrel: 35–45, Neck: ≤45 | ||

| AS70 II | C: 0.65–0.75, Si: 0.20–0.60, Mn: 1.40–1.80, Mo: 0.20–0.45 | Barrel: 35–45, Neck: ≤45 | ||

| AS75 | C: 0.70–0.80, Si: 0.20–0.60, Mn: 0.90–1.20, Cr: 0.75–1.00, Mo: 0.20–0.45 | Barrel: 35–45, Neck: ≤45 | ||

| AS80 | C: 0.75–0.85, Si: 0.20–0.70, Mn: 0.70–1.10, Cr: 0.80–1.50, Ni: ≥0.20, Mo: 0.20–0.60 | Barrel: 35–45, Neck: ≤45 |

Applications

Alloy cast steel rolls are widely used in roughing mills, finishing mills, and heavy-duty rolling operations, making them a cost-effective solution for steel producers worldwide.

At SATRAD GROUP, we supply high-quality alloy cast steel rolls designed to boost efficiency and durability in your production line. With nearly a decade of expertise, we are your trusted partner in metallurgy and industrial solutions. Contact SATRAD GROUP today to discuss your roll requirements.