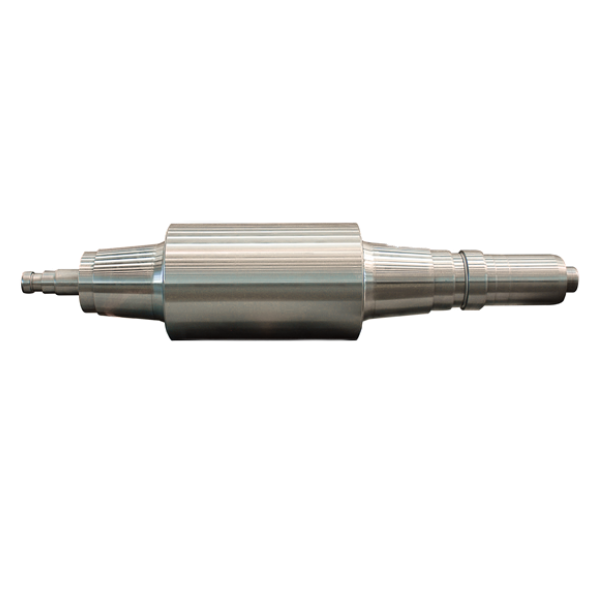

Roughing Rolls

What Are Roughing Rolls?

Roughing rolls are a critical component in rolling mills, primarily used in the initial stages of metal deformation. Unlike finishing rolls, which provide the final dimensions and surface quality, roughing rolls are designed to reduce the thickness of ingots or slabs rapidly and efficiently.

These rolls are commonly used in hot rolling mills, cold rolling mills, and universal rolling mills, making them indispensable in steel, aluminum, and non-ferrous metal production.

Key Functions of Roughing Rolls

- Initial Size Reduction

Roughing rolls reduce the thickness of metal from large slabs or billets to a more manageable size for subsequent rolling stages. - Surface Preparation

By applying consistent pressure, roughing rolls help prepare the metal surface for finishing rolls, ensuring improved surface quality and dimensional accuracy. - Material Flow Control

Properly designed roughing rolls help control the material flow, reducing defects such as warping or edge cracking.

Materials and Construction

Roughing rolls are subject to extreme mechanical stress, high temperatures, and friction. Therefore, they are typically made from high-strength alloy steels or cast steel with specialized heat treatments. Some high-performance rolls incorporate cemented carbide or high-chromium cast iron coatings for improved wear resistance.

Common roughing roll types include:

- Steel Roughing Rolls – suitable for moderate workloads and cost-effective solutions.

- Alloy Steel Roughing Rolls – provide enhanced toughness and wear resistance.

- Cemented Carbide or High-Chromium Rolls – ideal for heavy-duty rolling and long service life.

You can compare roughing rolls with other rolling mill rolls like Blooming Rolls and Finishing Rolls to understand their position in the rolling process.

Roughing Rolls vs. Finishing Rolls vs. Backup Rolls

| Feature | Roughing Rolls | Finishing Rolls | Backup Rolls |

|---|---|---|---|

| Purpose | Initial reduction of slab/billet thickness | Final dimensioning and surface finishing | Support work rolls to reduce deflection |

| Stage in Rolling | First stage | Final stage | Used alongside work rolls |

| Material | Alloy steel, cast steel, high-chrome, cemented carbide | High-grade steel, alloy steel | Forged steel, alloy steel, sometimes cast iron |

| Surface Finish | Moderate | High-quality | N/A (supportive function) |

| Typical Applications | Hot rolling, cold rolling, universal rolling | Steel sheets, strips, plates, precision products | All types of rolling mills needing work roll support |

This table helps clarify how roughing rolls fit into the broader rolling mill operation.

Applications

Roughing rolls are widely used in industries such as:

- Steel Production – initial rolling of slabs and billets.

- Aluminum and Copper Rolling – reducing ingot thickness before finishing.

- Specialty Metal Rolling – for high-strength alloys in automotive and aerospace industries.

Conclusion

Roughing rolls are the unsung heroes of metalworking, performing the heavy-duty task of initial deformation while setting the stage for precision finishing. Choosing the right material and design for roughing rolls is critical for efficiency, durability, and product quality in rolling operations.