Magnesia Carbon Brick

At SATRAD GROUP, we specialize in high-quality magnesia-carbon bricks, designed to meet the rigorous demands of the steelmaking and metallurgical industries. Our magnesia-carbon bricks are made from high-purity electrofusion magnesia and flake graphite. These bricks are bonded with a resin and enhanced with a composite anti-oxidation agent, ensuring outstanding durability and performance in extreme conditions.

High Working Temperature

Good Thermal Shock Resistance

Strong Slag Resistance

Low Creep Rate in High Temperature

Technical Data Sheet

| Item | MT – 8A | MT – 8B | MT – 10A | MT – 10B | MT – 12A | MT – 12B | MT – 14A | MT – 14B | MT – 16A | MT – 16B | MT – 18A | MT – 18B |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MgO, % | ≥82 | 81 | 80 | 79 | 78 | 77 | 76 | 74 | 74 | 72 | 72 | 70 |

| C, % | ≥8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 |

| Apparent Porosity, % | ≤4.5 | 5.0 | 4.0 | 4.5 | 4.0 | 4.0 | 3.5 | 3.5 | 3.5 | 3.5 | 3.0 | 3.5 |

| Bulk Density, g/cm³ | ≥3.05 | 3.00 | 3.02 | 2.97 | 2.97 | 2.94 | 2.95 | 2.90 | 2.92 | 2.87 | 2.89 | 2.84 |

| Cold Crushing Strength, MPa | ≥45 | 45 | 40 | 40 | 40 | 35 | 38 | 35 | 35 | 35 | 35 | 30 |

Application

What sets our magnesia-carbon bricks apart is their exceptional properties: low porosity, high-temperature strength, superior erosion resistance, and strong spalling resistance. These features make our bricks ideal for use in a variety of applications, from slag lines of ladles to lining of converters, AC electric arc furnaces and DC electric arc furnaces in the steel making industry. Depending on your specific smelting conditions, we offer different grades of magnesia-carbon bricks tailored to meet the precise demands of your operation.

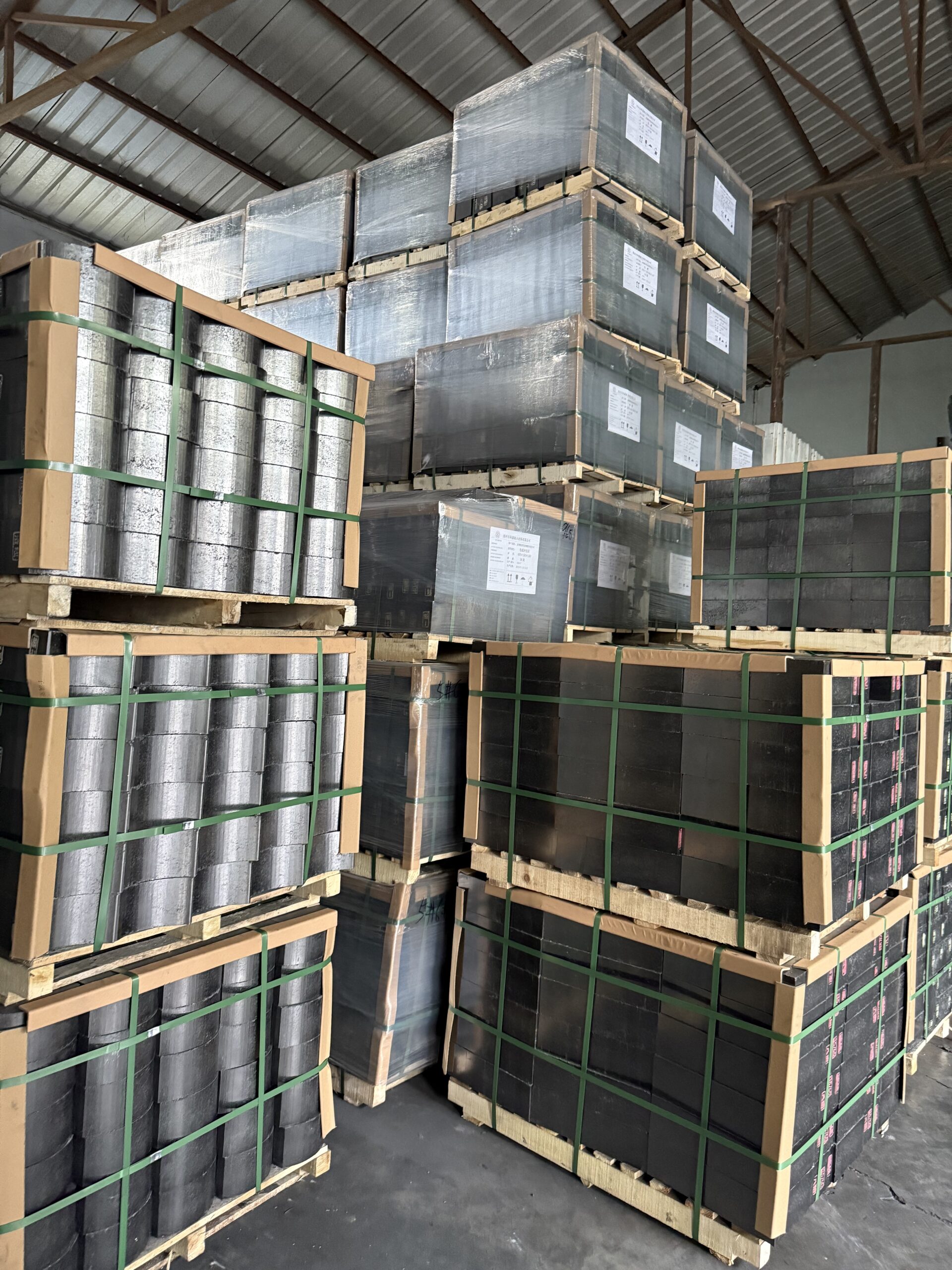

Our Packaging